‘SPOOL’ is the NEA coursework I completed as part of my Product Design A-Level and made up 50% of my final grade. This project ended up scoring 88/100 which I am very proud of as this is an A*, even if I had gotten an F on this project I wouldn’t be any less proud of it. The goal of this project was to create a functional, efficient and commercially viable solution to filament drying for 3D printers. The problem I set out to solve was wet filament, this is the material that a 3D printer uses to create 3D models and this material typically is hydroscopic meaning it easily absorbs the moisture from the air. This moisture contaminates the material and when extruded through the hot end of the 3D printer will evaporate causing surface defects and significant degradation of the materials properties such as strength. My aim was to create a product that will not only reverse the affects of moisture absorption but the prevent it from happening in the first place.

Throughout the process of designing, developing and refining this product I taught myself many new skills including:

Along with these new found skills I also utilised every other skill I obtain to achieve the best possible product

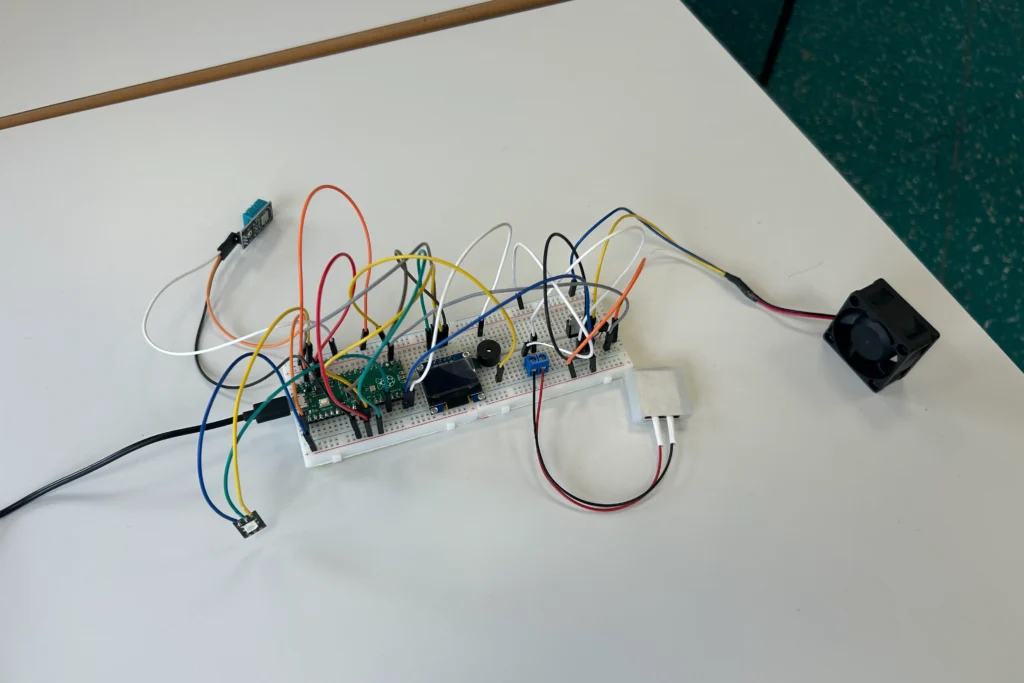

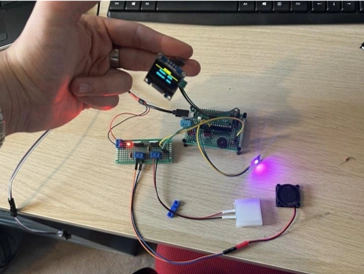

I believe that one of the biggest features that sets my product apart from others is the internal electronics. Many other ‘similar’ products that aim to achieve the same function as mine will be limited to purely silica gel to absorb the moisture out of the air and therefore the filament. However, this method requires the silica to be replaced periodically, this is not only impractical but also can be expensive. That’s why I chose to use the skills I learnt in my Electronics A-Level to develop and build my own custom circuit featuring a Raspberry Pi Pico microcontroller. This allowed me to write my own code that will automatically adjust the state of a heater and fan depending on the reading from the DHT11 temperature and humidity sensor whilst also controlling a small OLED screen and neopixel keeping the user constantly informed on the current state of the circuit and the properties of the internal environment. I have chosen to also include specially designed pockets hidden within the spool holder feature of the product. By providing more then one method of drying the material I have given the user the choice on how to dry their material.

One of my key focuses was modularity. I found this important as I wanted my product to be easily repairable by the consumer. I went about this by firstly focusing on the electronics as they are often the parts that fail first. I could’ve made the entire electronics assembly replaceable but this would’ve been expensive for the user. Instead, I decided to make a custom perfboard with female headers to allow each major component to be unplugged and a replacement easily plugged back in. This means that if only one electronic component were to fail the whole assembly won’t need to be replaced and just the individual component.

I also considered making my project open source which unfortunately I was unable to do due to the exam restrictions as this was 50% of my final grade. Although I couldn’t do this, if I were to do this I would start by making a repository on Github as this is a credible website where most open source projects are already hosted making it easily accessible to my consumers. I would have here instructions on how to remove and replace each component along with information pertaining to where they can be sourced. Having the code for the microcontroller and instructions on how to flash it is also important as this component cannot simply be unplugged and plugged back in.

Finally I would have the CAD files for the parts that are 3D printable. This means that if one of the 3D printed features were to break another one could easily be remade by the consumer provided they have access to a 3D printer.

One requirement of this project was to work closely with a potential client and stakeholders to gain their advice and feedback. For this I chose not only to work with an in-person client that I could sit down with but also two large companies dominating the 3D printing industry as my stakeholders. These two companies were Prusa and 3D Jake, across the course of my project I maintained contact with these two companies exchanging emails discussing specific requirements that my product should have, regular updates and finally feedback on the final product. Thanks to this I was able to achieve a much more sleek functional product. I valued the all the help and feedback I gained from working with these two companies and I hope to do more projects like this in the future.

Developing suitable packaging was difficult as I wanted to be sustainable but this was a large product so a convenient cardboard box wouldn’t be feasible. I cycled through a few different ideas until I landed on using ‘bumpers’ on all edges and corners. This way the whole product is protected whilst still only using minimal materials. Banding spans vertically and horizontally across the product holding on 8 cardboard bumpers on of the furthest protruding points.

To create these bumpers I used 2D design CAD to create the cross section of the bumper. I did this so I could then laser cut these out of cardboard and layer them up using glue to form the bumper, this is effectively the same as extruding the cross section shape.

One of the limiting factors of my product was the power supply. I designed it to run off 5 volts 1 Amp as this is the input voltage that I supplied to the Raspberry Pi Pico. This limited the size and power of both the air circulating fan and the PTC heater. After speaking to stakeholders Prusa and 3D Jake they suggested to use a different more powerful power supply for these components and then use a relay to allow the Raspberry Pi to still control the heater and fan.

Since this project finished I have already made a few improvements to the design. The first improvement I made was to compress the overall size of the electronics and the electronics housing making it fit neater within the product resulting in a more aesthetic fitment and will also allow larger spools to fit more comfortably within the product.

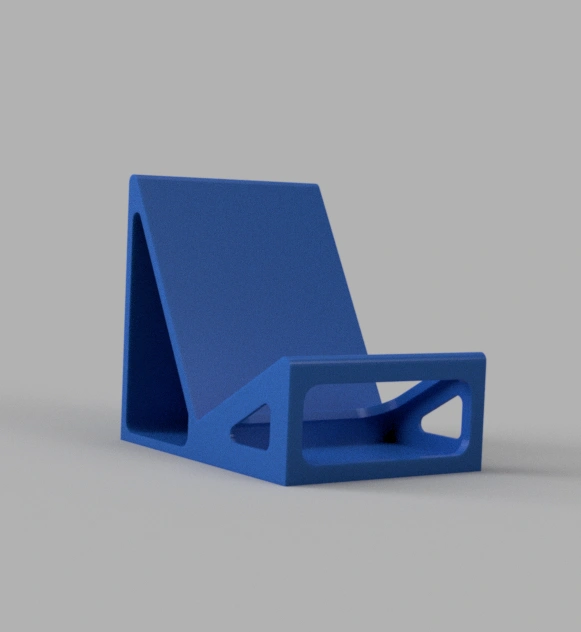

The product had two positions it could be used in, horizontally on its back or vertically on the wall. Whilst this was usable it did limit the ways it can be used. To solve this I have designed and 3D printed a stand that would hold the product vertically at a slight angle allowing the PTFE fittings underneath to remain accessible.

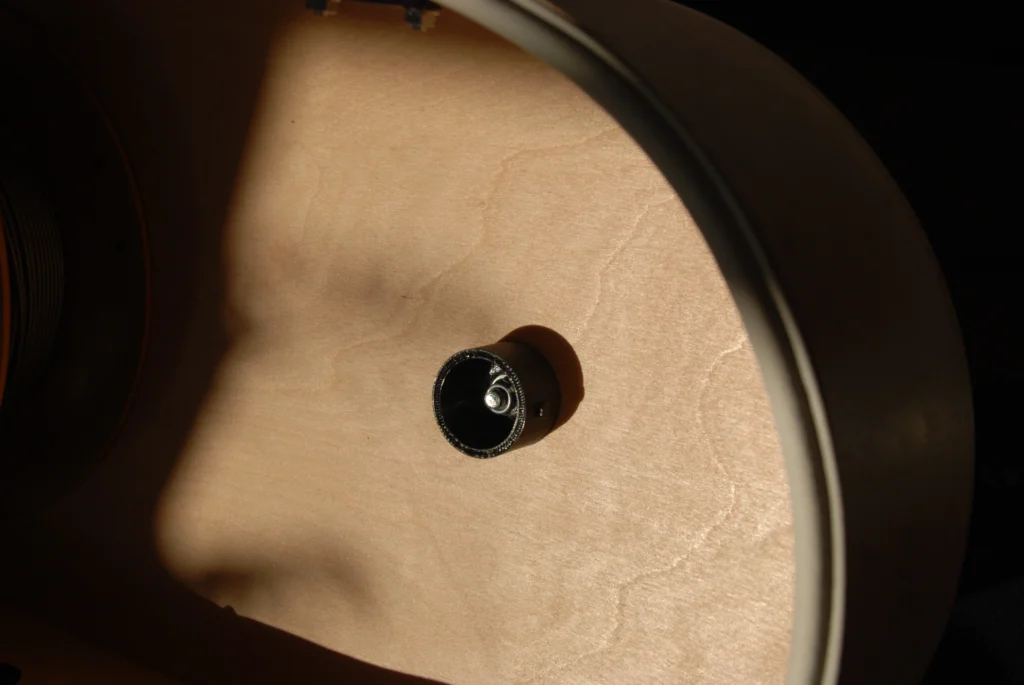

The final improvement I have made thus far is a shroud and mount for a 40x40mm fan. This fan will intake air from within the internal environment of the product that would have a high humidity from drawing the moisture out of the material and then disperse this humid air past the seal of the door and into the external environment. This keeps the humidity low within the product allowing more moisture to be drawn from the moisture.

After submitting this product for marking I was made aware that it had won the ‘3 Dimensional Design Creative Arts Award 2025’ at Shrewsbury Colleges Group. This award was parts of a larger yearly event known as ‘The Show’, I attended this where I was presented the award along with a small cash prize form the principle James Stainforth in front of an audience. I was very proud to achieve this award as it demonstrated to others my skills along with showing me that all the hard work was worth it. To be able to call myself an award winning Product Designer is a privilege I am very grateful to be able to have.